Business

We design and manufacture the Reverse osmosis plant according to the client need

R O Plant (Reverse Osmosis Plant)

Reverse osmosis-manufactured plants are used to produce high-quality demineralised water, especially where the client looks to minimise the use of chemicals which are the regenerants associated with the more conventional demineralised ion exchange process__________________________________________________________________________________________________________________

Reverse Osmosis Plant

Our water treatment system, RO plant are used for reducing levels of suspended particles and dissolved solids and applicable for removing various bacterial contaminants present in the water. These RO plants, water purification plants are widely acclaimed for its effectual performance and high efficiency. We, at Hyderabad Sruthi Engineering Company, have reverse osmosis plant to clean and purify water by removing salts and other impurities to improve the taste or properties of the water. Our plant is well equipped with all the instruments and required facilities to meet specific customer needs.

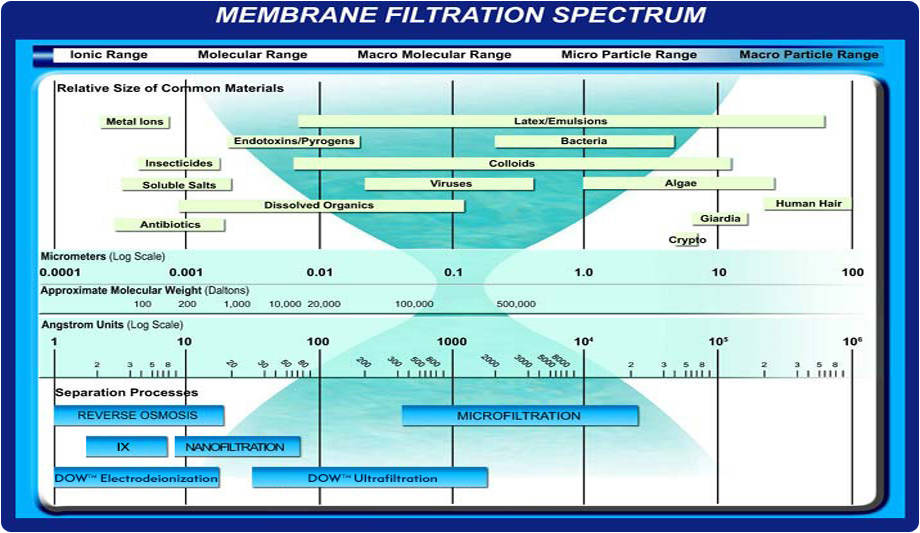

The company prefers high quality reverse osmosis membrane elements to ensure flawless operation. Reverse osmosis (RO) was the first cross flow membrane separation process to be widely commercialized. RO remove virtually all organic and inorganic compounds 90 to 99% of all ions. We have a large selection of reverse osmosis membranes to meet varying rejection requirements. The cross flow mode of filtration continuously sweeps the membrane surface clean of impurities, which allows for many hours of trouble free and continuous operation between chemical cleanings.

Within a short span, we have successfully emerged as one of the leading manufacturers of Water Treatment Plants. We offer in our range Waste Water Treatment Plant, Reverse Osmosis Plant, Water Softener, Sewage Treatment Plant, Effluent Treatment Plant, Demineralizer and Water Treatment Plants. Our products are known for effectively cleaning water, rapidity and tolerance capacity. These are designed and developed in accordance with a well planned working methodology to provide the best quality.

It is more energy efficient as compared to heat driven purification (distillation) and more efficient than the strong chemicals required for ion exchange. In this process, no energy – intensive phase change is required. Pores in reverse osmosis membranes are so small they have not yet been resolved, even by the most advanced microscopic techniques. These are generally regarded to be in the 0.0001-micron range, four orders of magnitude smaller than the finest of the normal – flow particle filter.

Working Process:

• Raw water from the bore well/Source is pumped by means of the pump to Storage Tank.

• After chlorination and retention time period water pumped through Pressure Sand Filter for the removal of suspended impurities, mud and organics.

• After water will passed through activated carbon filter for the removal of inorganic impurities, bad taste and odor by the adsorption process that is these are retained by the surface of the granulated carbon and subsequently recharged once the backwashing is done with water.

• Anti-scalent dosing system will be dose online.

• The water is then passed through Micron Filter where in particulate matter of size up to 5 micron and 1 micron the cartridge retains.

• The filtered water then passed through R.O System by presurising the water, reject water will be drain out and (permeate water) treated water is passed through UV system and collect to storage tank and if required done online mineral dosing to maintain TDS of treated water.

• Then treated water re-circulates to ozone tank through pump and simultaneously passed through 0.45 micron and 0.2-micron filter to filling section.

• Actively rejects ions and contaminants.

• Reduce water that meets the most demanding specifications.

• Allow the membrane to continually clean itself.

• Higher pressure from the pump to push the fluid through the membrane.

• Capable of rejecting bacteria, salts, sugars, proteins, particles, dyes, and other constituents.

• Works in various molecular weights. Features: 1. Fully automatic PLC control starting system 2. With compound FRP quartz sand and active carbon filter to save space 3. With Chemical dosing system Applications

• Homes. • Offices. • Resorts. • Hospitals. • Industrial Houses. • Residential Colonies. • Educational Institutions • Community Drinking water